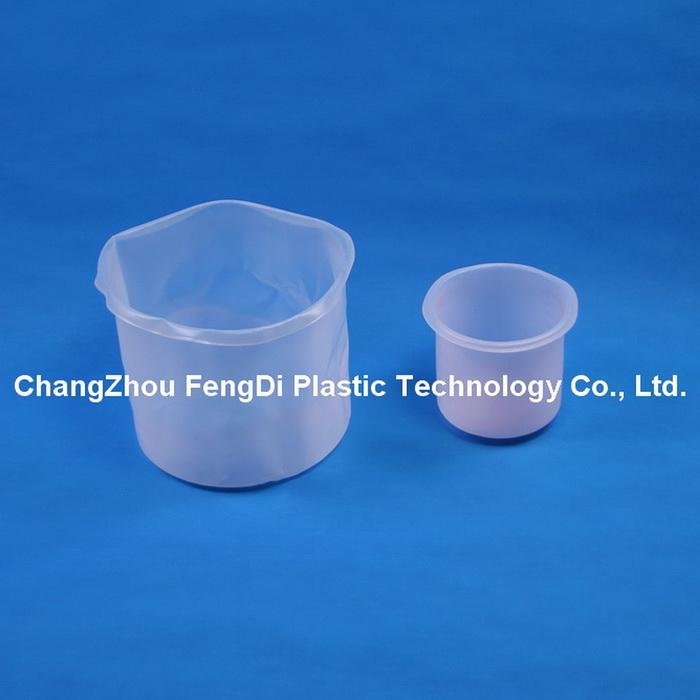

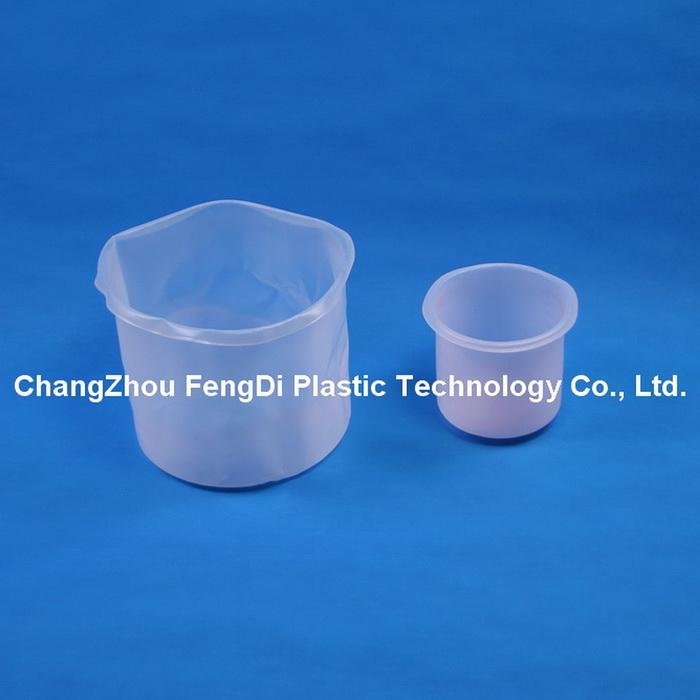

Product Description

Spray Paint Pressure Pot Tank Liners

Material: HDPE or Polypropylene

Model Compatibility:Gal Pressure Tank

Style :Disposable

Type: Pot Liner,Tank Liner

Volume :2L to 220L

Product Weight :according to different type of tank liners

UOM: each

Semi-rigid pressure tank liners custom made of tough, durable,high density polyethylene with "anti-static" additive to minimize static electricity build-up in shipping and handling.

Ideal for use with all materials that are compatible with polyethylene.

Made of tough,durable,high density polyethylene and HDPE

Will not contaminate materials

Anti-static

Allows quicker color changes

Time saving clean up

Reduces solvent cost in clean up

Used with Binks,DeVilbiss and other brands Pressure Tanks pressure pots.

A disposable tank liner is supplied with all pressure tanks as standard.

Made from anti-static material,disposable for easy clean-ups, most economical way to run most applications and reduces costly downtime

Related Liner Products: Drum Liners,Barrel & Drum Linings,Plastic Liners, pot liner,Tank Liners, Box Liners,Basket Liners, Gaylord Liners,Anti-Static Liners,Pail Liners,Paper Liners,Cargo Liners,FIBC Liners,Cap Liners,Liquid Liners, Fabric Liners.

Thermoforming and Vacuum Forming

Thermoforming and vacuum forming are fast and inexpensive technologies for manufacturing versatile products by shaping hot thermoplastic sheets around a mold. Once the sheets are drawn onto the mold, any remaining air is sucked out of them, pulling the material tightly against the mold to ensure consistent definition in the final product. Once the product is taken off the mold, the excess plastic is trimmed off and recycled.

It requires less lead time and tooling costs than traditional manufacturing techniques like injection molding or machining while also offering a lower part cost than 3D printing. Although thermoforming has more design limitations than these technologies, it offers excellent value for compatible projects.

With a variety of materials available, our thermoforming services are ideal for a range of products, from custom trays and packaging to large panels, displays and housings.

Price Terms︰

EXW/CFR/FOB

Payment Terms︰

TT

Lead Time︰

within 20 working days

Product Image